When you have a job to get done, you need to make sure your tool won't let you down! Here are our 2 pieces of advice to make the right choice.

1. Consider the application

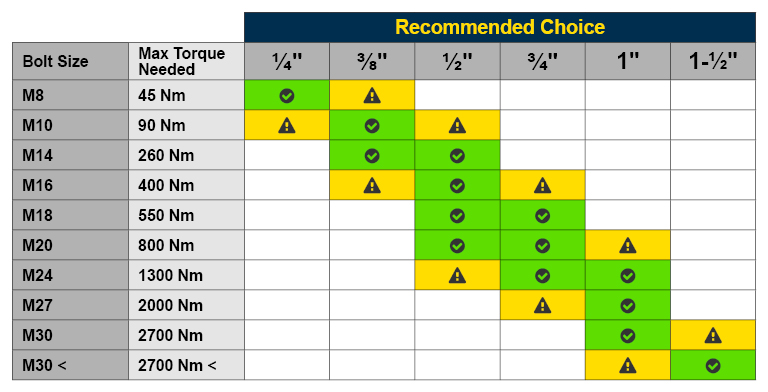

The most important thing is to make sure your impact wrench has the right torque needed to finish the job, and each application has different requirements. In the following table, you will easily find the most suitable size to un-tighten each bolt size category.

Did you know?

Just like you move up a gear when you need to drive faster, you need to choose the right tool for your application, and depending on the job you might need to select a more powerful tool. To secure your purchase, make sure the maximum torque required by the application matches the tool’s working torque (in green in the table), and not the tool’s maximum torque. For a frequent use of the tool at its maximum torque level, we recommend to choose a more powerful tool (in yellow in the table).

2. Check your airflow and airline network

Correct air flow + right accessories = tools performance

Pneumatic tools need air! Don’t underestimate the impact of the airflow and the airline network on their performance. First, to get the right air flow, check at the compressor’s level if the available air flow is sufficient to meet the tool’s requirements. Great! Now let’s make sure that your tool is getting all the benefits by simply following these recommendations:

- Check the minimum hose size needed for your tool and use adapted accessories, such as FRL, couplings and hose reel, this way you won’t lose any air power between the compressor and the tool,

- Use an FRL for each tool, it will clean and lubricate the air entering the tool as well as ensure air consistency.

Did you know?

Most of air tools work with a 6.3 bar air pressure. To ensure the correct setup, we recommend you to allow a higher air pressure at the compressor's level, and set up the 6.3 bar measure at the FRL level.

As a summary, here are our key advice to make the right choice:

- Check the torque needed for your application and select your tool accordingly

- Look at your compressor and your airline network: make sure you will meet the airflow requirements and that you have the right accessories. All the information you need is in the operator manual, provided by the tool's manufacturer, or contact your distributor for any support.

Short listing the tools? Other criteria can help your choice and differentiate tools from each other. Not even mentioning the price, it is really a good thing to look at the tool’s ergonomic aspect (weight, comfort…) and the tool’s durability (is the tool adapted to your working conditions? Are you going to make an extensive use of the tool?)